What is Air Circuit Breaker?

A circuit breaker in which the contacts open and close in air at atmospheric pressure is defined as an air circuit breaker.

What Does ACB Stand For?

Air circuit breaker is an electrical full form of ACB

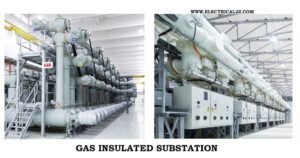

The oil circuit breaker developments described above led to almost complete replacement of the earlier designs of air circuit breakers in medium voltage distribution systems by oil circuit breakers in many countries.

Want to Read About Oil Circuit Breaker?

However, in some countries, notably France and Italy, the air circuit breaker was developed and used for systems up to 15 kV, but in general, its use is restricted to low voltage applications or high security installations where the risk of an oil fire or oil contamination of the environment is too high to be tolerated.

|

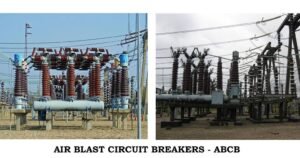

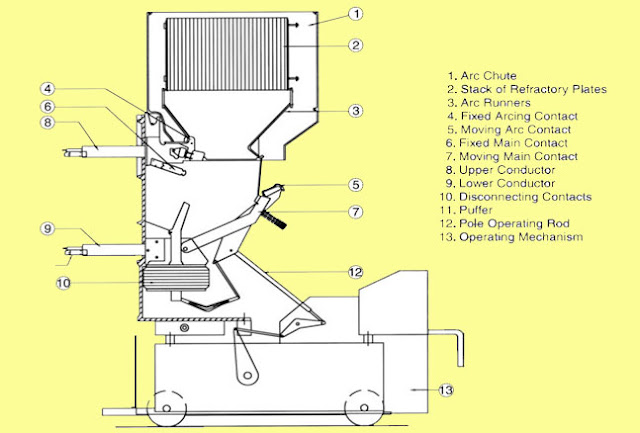

| Main Parts of an air circuit breaker trolley |

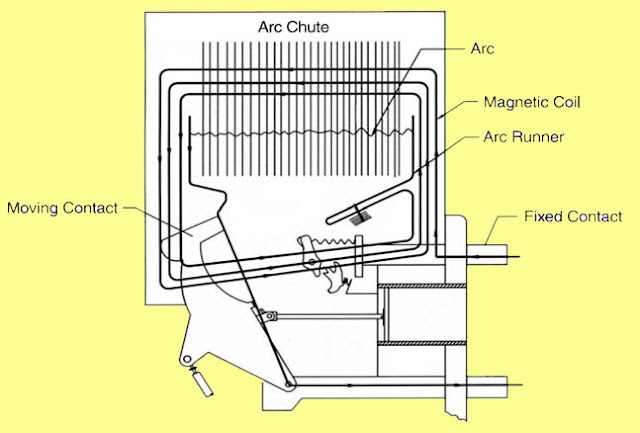

Countries following the American practice used air circuit breakers almost exclusively for systems up to 15 kV until the advent of the new vacuum and SF6 technologies. Image shows main parts of an air circuit breaker trolley.

The principles of arc interruption followed in an air circuit breaker are rather different from those in any other type of circuit breaker. While the objective of both types of circuit breakers is the same, i.e. to prevent the resumption of arcing after current zero by creating a situation wherein the contact gap will withstand the system recovery voltage, the air circuit breaker does this by creating an arc voltage in excess of the supply voltage.

This can be done in three ways:

• Intense cooling of the arc plasma, so that the voltage gradient is very high.

• Lengthening the arc path to increase the arc voltage.

• Splitting up the arc into a number of series arcs.

|

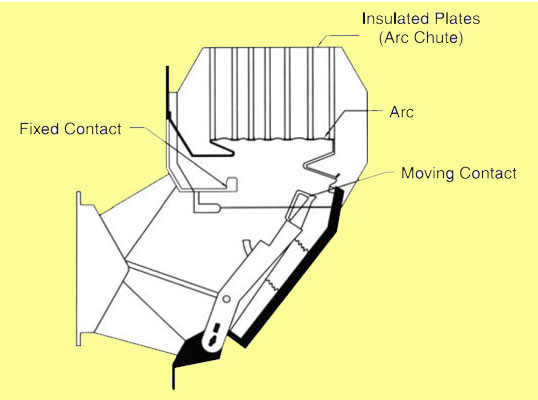

| Cooling arc in an insulated plate arc chute |

The first objective is usually achieved by forcing the arc into contact with as large an area as possible of insulating material. All air circuit breakers are fitted with a chamber surrounding the contact and arc zone, usually called the ‘arc chute’, because the arc is driven into and through it.

If the inside is suitably shaped, and the arc can be made to conform to the shape, the arc chute walls can help achieve cooling. This type of arc chute needs to be made from some kind of refractory material, with asbestos compounds once being the favored choice. However, because of increasing awareness of the health hazards associated with the use of asbestos, other materials such as high temperature plastics reinforced with glass fiber and ceramics are being used for this purpose. Image shows cooling of arc in an insulated plate arc chute.

The second objective is achieved concurrently with the first, if the walls of the arc chute are shaped in such a way that the arc is not only forced into close proximity with them, but also driven into a serpentine channel. The lengthening of the arc and the simultaneous increase in the voltage drop per unit length soon lead to a high arc voltage, and a high arc resistance.

|

| Arc chute with magnetic coil |

This changes the system power factor so that the instantaneous value of the supply voltage as the current approaches zero is much below its peak value. Finally, the high value of resistance represented by the arc influences the damping of the TRV oscillation such that the amplitude factor is reduced almost to unity.

The preceding paragraphs explain what is required, and how to achieve it, but a heavy current arc is an intractable thing and one of its main tendencies is to keep itself as short as possible since that helps to maintain its ionization level, and hence its current-carrying capability. Thus, while it is not difficult to design convoluted walls to arc chutes, it is also not easy to persuade the arc to enter them!

The usual arrangement of an air circuit breaker is to arrange the arc chute above the contacts, and enable the contacts and the connections leading to them to form a tight loop so that a magnetic field is produced within the contact gap acting upon the arc in such a manner as to drive it up into the chute. In this design, increase in fault current results into increase in magnetic field which elongates the arc and thus helps in arc extinction process.

The use of the magnetic circuit complicates the contact structure, as it is not advisable to retain the coils in circuit continuously, and arrangements have to be made to insert them into the arcuit during the opening of the circuit breaker. This is usually achieved by splitting the arc runner, a metal strip that runs up from each contact to guide the arc into the required path so that the coil is automatically inserted into the current circuit as the arc runs up towards the chute. Refer Figure showing an arc chute with magnetic coil.

|

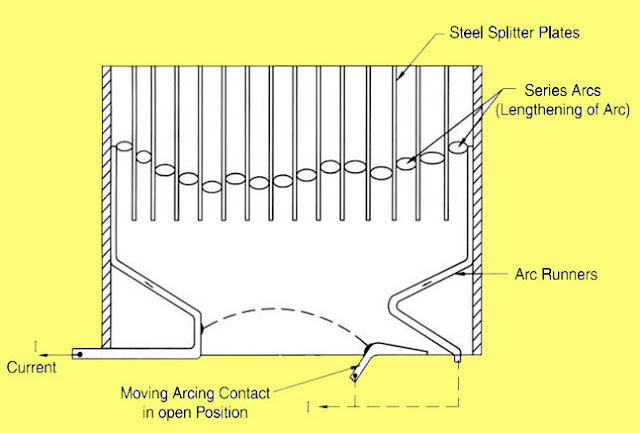

| Arc chute with metal arc splitter plates |

The heavier the fault current, the more effective will be the air circuit breaker, until it either becomes so effective that the arc runs straight through the arc chute and re-establishes itself as a nice short arc outside the chute, or the pressure inside the chute below the plates, created by the arc, becomes so great that the arc is prevented from rising into the plates. Either case obviously constitutes the upper limit of breaking capacity for a given arc chute, which needs to be at a respectable margin above the designed rating.

When it is interrupting maximum fault current, an air circuit breaker, rated typically at 40 kA and 12 kV, would emit an impressive fireball from its arc chute, if a large cooling baffle is not fitted to contain it. The result is that air circuit breakers of heavy ratings constitute large, heavy and expensive pieces of plant and machinery. They do, however, have advantages for certain applications, particularly where the system switching parameters are severe, as the high arc resistance makes the air circuit breaker virtually independent of the circuit in which it is connected.

However, the third technique can facilitate a reduction in energy generation by using metal arc splitter plates refer image in the arc chute, which not only increases the voltage gradient, but also helps to introduce a large number of anode and cathode voltage drops. A combination technique has been designed which uses an assembly of small arc chutes which are individually of the ‘cooling and lengthening’ type, but which are collectively arranged such that the initial arc is split into a number of series arcs, each in its own mini arc chute. This is a more complicated design but one which is suited to higher distribution voltages. It also has another advantage in that it eliminates the need for providing extra components for the creation of a magnetic field in order to drive the arc into the chute.

Thus the art of designing an effective air circuit breaker requires the correct combination of chute shape, magnetic field development and air puffer to facilitate a uniform arc extinction performance over the whole current range. Several parameters have to be balanced for this, including some that have not yet been mentioned such as arc chute height, length and outlet area. The mechanical forces developed in a heavy-duty air circuit breaker are also considerable.

A final point concerning the characteristics of the air circuit breaker is that the interrupting technique described above is the only one that does not really depend on the presence of a current zero. If the arc voltage can be made to exceed the supply voltage, the arc will be extinguished, irrespective of whether the current is ac or dc, which makes it suitable for the control and protection of dc circuits.

Although these circuit breakers are considered obsolete for medium voltage application, they continue to be preferred choice for high current rating in low voltage application.

Final Word

Hope you understand this article about Air Circuit Breakers | ACB Breaker. Incase of any doubt please comment below. Subscribe our website to get every new post update to your email. Please follow our website – ElectricianWorld.net for future updates. Thank you for visiting our website.