GI Conduit Pipe and PVC Conduit Pipe are the two types of electrical conduit pipes. In the electrical installation, conduit pipes are used for the electrical cable protection. It is an enclosure type. There are three types of electrical pipes are used in electrical construction.

GI, PVC and Flexible metal are three types of electrical conduits. 20mm, 25mm and 32mm are different sizes of conduit pipes used in the electrical pipe installation works. Coupler and glue are the two main material used for PVC installation work. GI bender machine and adjustable wrench are used for the GI conduit installation work.

Table of Contents

Installation of Electrical Conduit Pipe

Junction boxes, in-risers, out-risers and reducers are the electrical conduit fittings. GI bender machine is used for making GI conduit pipe installation. Only flexible metal hose is available in two sizes are 20mm and 25mm.

This electrical installation is a part of closed wiring system for ensure the cable protection. Wall installation depth of the PVC conduit is 50mm. Before starting the civil construction works, should be done PVC conduit installation works by electricians.

Interview tip: GI stands for Galvanized Iron and PVC means for Polyvinyl Chloride. Click the link to read more electrical abbreviations and its full forms.

Electrical Conduit Pipe Types – GI Conduit Pipe and PVC Conduit Pipe

There are 3 types of conduits are popularly used in the electrical construction. They are,

- PVC conduit pipe

- GI conduits

- Flexible metal hose

PVC Conduit Pipe

20mm, 25mm and 32mm are three sizes of PVC conduits. Glue is used to joint the pipe with coupler. Screws, fisher and steel wire are used to fit the PVC pipe with floor or wall. Spring bender is used for bending the PVC conduits. For Using bender machine to make offset. 20mm and 25mm are the two sizes of spring bender. Hammer is also need for this installation.

GI Conduit Pipe

20mm and 25mm are the two sizes of GI conduit pipes. GI bender machine is used to make a bended pipes. Bender machine have a two types of dies. We should have to put the pipes in dies. Dies only used for holding purpose. The bender machine is designed by semi-automatic. So, the electricians need to give bulk energy to the bending.

We must have drilling machine for the pipe installation work. We need to make 10mm width holes to fix the pipes properly. 8mm bit is used for this operation. 10mm unifix is used in the walls to holding the pipes. Hacksaw blade with frame is used to cut the pipes in half or needed length. Screwdriver and file also needed for pipe installation work.

Required Tools

Spring bender is the tool which is used to bend a pipe. Sizes of spring bender is 20mm and 25mm. Electricians always keeps a bender in their tool boxes. Electrical pipe installation is based on the single line diagram which is given by the consumer plan. In the single line diagram, designing engineers must mentioned the pipe size, route, location, and number of conductors.

Why are we using electrical conduit pipes?

The electrical conduits are used to protect the electrical cables. Electricity is one of the dangerous thing in the world. Even though the conductors that carry the current is insulated by some PVC covered materials or rubber, the insulating material is not strong enough to protect the cable from damage.

When the insulation is damaged, the electrical conductor inside may be exposed to touch or it can also unintentionally come into contact with things that can carry electric current. This scenario would present a high risk of electric shocks. Therefore, we protect the electrical cables so that they do not present the dangers of electric shocks to people.

A second reason to protect the electrical cables is to make sure the electrical system stays reliable. When the cable PVC covering is damaged, the conducting metal can come into contact with other metals that are in contact with earth. When this happens, the leakage protection of the electrical system will automatically trip the circuit breaker controlling the circuit whose cable has been damaged.

Damaged electric wiring cables can cause this tripping at time we need the electricity most. Therefore, electrical conduits are used to provide this reliability.

Electrical conduit must be installed rigid, permanent and without sag. It should also be able last with integrity for the design life of the building. What if the building can last 50 years? Should the conduit installation be able to last 50 years also? Well, if it can, then we did the proper installation or we have a luck. Whatever, electrical wiring system will not be good enough 50 years from the time the building is constructed.

Technology change, how people use electricity change, the personal taste and preference of the people occupying a building space and design also change. All this will result in the need to renovate the building, and most likely the electrical wiring system also. The electrical conduit pipe system would not need to last 50 years. However, it should be last in 30 years.

Therefore, once installed, the electrical conduit should be rigid, permanent and strong. Electrical installation specifications usually specify the maximum distance between conduit saddles. Distance between the one to another saddle is 900 mm to 1100mm. It varies about country.

The size of the conduit, the materials and the installation environment also are among the major factor in determining the maximum distance between the support saddles that is allowed. The length of the conduit pipe is commonly 3000mm to 3300mm.

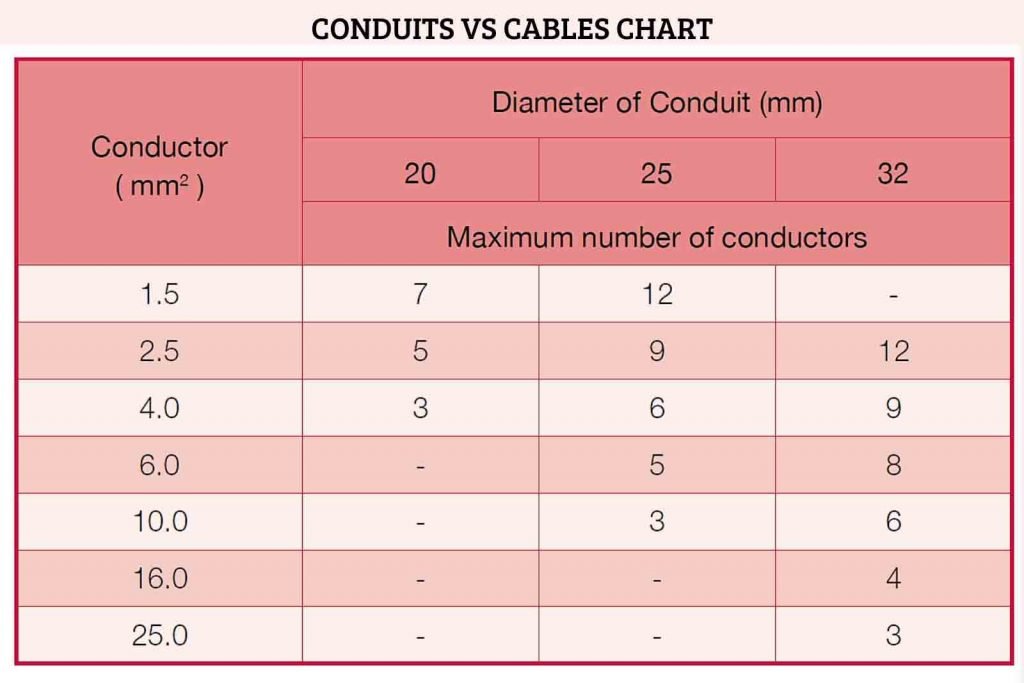

Conduit Pipe Size Chart

| Diameter | of | Conduit | |

| Conductors (mm2) | 20 | 25 | 32 |

| Maximum | number of | conductors | |

| 1.5 | 7 | 12 | – |

| 2.5 | 5 | 9 | 12 |

| 4 | 3 | 6 | 9 |

| 6 | – | 5 | 8 |

| 10 | – | 3 | 6 |

| 16 | – | – | 4 |

| 25 | – | – | 3 |

| Conduit | Pipe | Size | Chart |

Final Word

Hope you understand this article about the electrical conduit pipe types and sizes. Follow our ElectricianWorld.Net website. Please share your experience with through the comments. Your comment can help me to improve my site updates. And if you think my post was something worth reading, then please share it with your social media friends.

In dubai we follows British standards for the electrical installation.. So we only use two types of conduit pipes. GI and PVC. Thanks for sharing your knowledge..

Electrical conduit pipes are only used in the building?

Yaa it's good site for learning.

Thanks

copex conduit

Does anybody know the thread size used on 25 mm conduit? I know it’s not BSP.

This is a very nice platform everything here is really interesting thanks