Table of Contents

Cable Crimping Tools or Connector Tools: Hydraulic Pump

Hydraulic pumps are used to ensure that all sizes of aluminum conductors can be properly terminated. They are also used in bending aluminum cable when it is of such diameter as to require the extra pressure afforded by a hydraulic device.

A hydraulic pump for aluminum connector tools exerts high pressure to crimp or squeeze lugs onto aluminum cable. Before compression, a typical cross section of electrical cable and lug(connector) consists of about 75% metal and 25% air. After compression, the cross section is hexagonal and, with the force provided by a hydraulic compressor tool, 100% of the metal makes contact with the wire with no air spaces between the cable wires and the lug or terminal.

An aluminum connector and tool consist of a pump to which is attached different sizes of heads. If a source of electric power is available, an electric motor is used to drive the hydraulic pump. If power is not available, a portable generator is used to supply power, or a hand-operated pump is used.

|

| Before and After Compression – Hydraulic Crimping Tool |

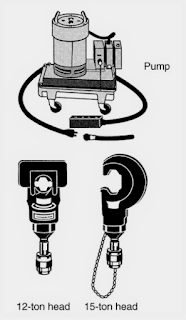

Hydraulic Pump

Hydraulic pumps are used to crimp for aluminum connector tools come in vary sizes. Figure is illustrates a typical pump. It weighs only 95 pounds and operates on 120 volts AC. It has a 1-horsepower motor that can pump 115 cubic inches of hydraulic fluid per minute at 2500 pounds per square inch or 57 cubic inches per minute at 10,000 pounds per square inch. Foot- and hand-operated switches are used to control the motor, which, in turn, drives the pump. The high pressure generated provides the force to crimp the aluminum cable.

|

| Crimping Tool |

Heads – Hydraulic Pump

The heads are the tools that actually do the work of compressing the cable and lugs to make good, tight fits.

Heads are available in different sizes to fit the requirements of particular jobs. They are identified by the amount of pressure they are able to exert on a connection. Three common types of heads are shown in Figure.

Twelve-Ton Head – Cable Crimping Tool

The 12-ton head is a versatile tool designed for field or bench work. The small size of the compression head and the fact that it can be operated by a switch located nearby but not on the pump, allows the pump to be in one area where there is space, and the head in a confined area where the connection has to be made.

The 12-ton head, shown in Figure, is made from forged steel. It weighs 71/2 pounds. When in use, it can apply 12 tons of pressure, or 24,000 pounds per square inch. The dies that fit into the head are color-coded to match color-coded connectors. A 12-ton head installs aluminum lugs and splices wire from 12 to 750 MCM.

Fifteen-Ton Head – Cable Crimping Tool

The 15-ton head can apply 30,000 pounds per square inch of pressure. It is used to install aluminum lugs, taps, and splices for #12 AWG to 1000 MCM. The 15-ton head shown in Figure, weighs 151/2 pounds and can be operated up to 100 feet from the electric hydraulic pump. Compression dies are available in two types: one that fits directly into the head and is used for large cables; and one that is used in combination with an adaptor for small conductors. All dies are color-coded to match the color-coded connectors.

Forty-Ton Head – Cable Crimping Tool

The 40- ton head makes connections with cable up to 2000 MCM with its 80,000 pounds per square inch of pressure.

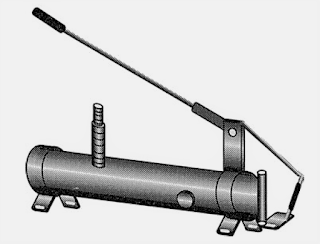

Manual Pumps (Hand or Foot Operated)

A manual pump aids in getting a number of jobs done in the field. These pumps can be used to bend conduit and apply pressure on connectors for taps and lugs as well as splices. See Figures shows channel hole punch.

It can be used in vertical or horizontal positions. The long handle on most models makes it possible to apply a great deal of pressure on the pumping apparatus and obtain the needed squeezing power to make a good electrical connection. In some cases, a hand- or foot-operated hydraulic pump can also be used to make punches for circuit breaker boxes, metal studs, or other steel boxes.

|

| Hydraulic Crimping Pump |

Using a Manual Pump

There are a number of operations to perform or observe before operating the manual-type pump.

1. Before using the pump, check all hoses for leaks and cracks.

2. Check that all safety valves are operating.

3. Always wear goggles when using a manual pump.

Wire Dispenser

A wire dispenser is a device that holds and dispenses wire. One common type is shown in Figure. This wire dispenser handles six 2500-foot spools of wire up to 18 inches in diameter. The dispenser itself can be passed through a standard 30-inch doorway. The front wheel is swivel-mounted to allow feeding in any direction from a central location and can be locked to prevent movement. Wire is paid out easily, and there is automatic braking.

There are less expensive models. They are available with the ability to handle spools of 500 feet of wire. They do not usually have automatic braking.

Final Word

Hope you understand this article about the Types and uses of Cable Crimping Tools or Connector Tools: Hydraulic Pump. Incase of any doubt please comment below. Subscribe our website to get every new post update to your email. Please follow our website @ElectricianWorld.Net for future updates. Thank you for visiting our website.