Table of Contents

Different Types of Lights

The installation, troubleshooting, and repair of lighting systems are some of the most common tasks of an electrician. Familiarity with the basic types of lights or lamps and lighting fixtures and with systems for controlling lighting is essential for any electrician or apprentice.

The National Electric Code (NEC) classifies lamps as incandescent or electric discharge. Incandescent lamps have a filament that glows white-hot. Lamps that produce light without a filament are classified as electric discharge lamps.

- Fluorescent lamps

- Mercury vapor lamps

- Metal halide lamps

- Some other types of lamps are classified as discharge types.

Electric discharge lamps operate by passing current through a gas-filled envelope. In some cases, they may have a filament to get started.

Incandescent Lamps – Types of Lights

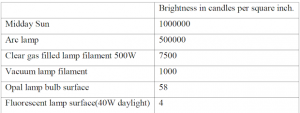

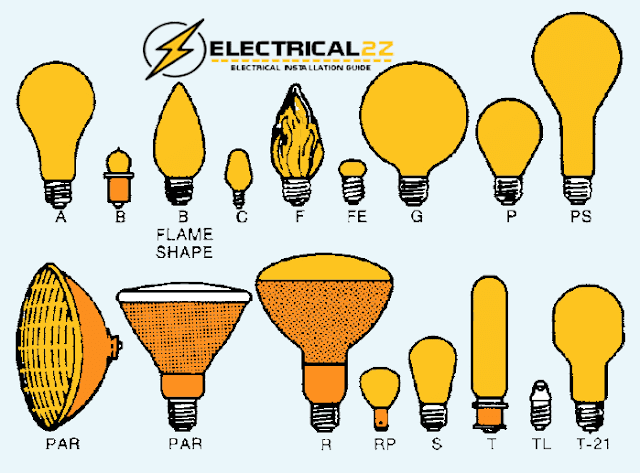

An incandescent lamp has a filament made of tungsten. When the tungsten becomes white hot, or incandescent, it gives off light and heat. Incandescent lamp filaments are available in a number of sizes and shapes. See the figure below. Incandescent lamps differ in their output, bases, wattage, and life expectancy.

|

| Filaments of incandescent lamp – Types of Lights |

One type of incandescent lamp that has a very high output is the quartz bulb. This bulb has a filament that glows inside a quartz tube. It operates at extremely high temperatures. The main advantage of the quartz bulb is its constant light output over its entire operating life. Quartz bulbs are used in automobile headlights and for dome lights inside a car.

A quartz bulb cannot be touched when hot or cold because the quartz bulb will absorb any oil on the hand, and its surface will be damaged. So, remember to use gloves when handling quartz bulbs.

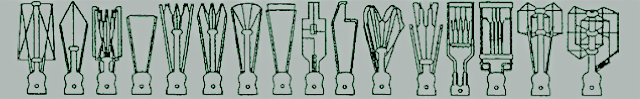

Bases of Incandescent Lamps

Most incandescent lamps for home use have a threaded base that is referred to as the Edison base. The threads on the base screw into matching threads on a socket. A base of the same shape but much larger in diameter is called a mogul base. It is usually found on bulbs that have high wattage capacity, draw high currents, and operate on 220 volts or higher. Mogul bases are also used on some mercury vapor lamps.

Some incandescent lamps have a bayonet base: two pins protruding on opposite sides of a smooth metal base. The socket into which bayonet-base lamps fit has a spring-metal contact at the bottom and two L-shaped channels on opposite sides of the socket wall that correlate to the pins on the lamp. The lamp is inserted by sliding the pins into the channels as far as they will go, which includes pushing against the spring-metal contact, and rotating one quarter turn. With this action, the pins then slide into the horizontal leg of the L-shaped channel, holding the lamp firmly against the spring-metal contact.

|

| Popular incandescent lamp bases – Different Light Types |

Figure shows various bases, including miniature and other types of lamps. Each is designed to make good electrical contact and provide support for the bulb.

Wattage and Life Expectancy

The wattage rating of a bulb is directly related to its light output: the higher the wattage, the greater the light output. Wattage, in turn, is directly related to the voltage applied to the filament and changes with any increase or decrease in voltage. An increase in voltage over the rated wattage of the bulb decreases the operating life of the bulb. Lower voltage gives longer life but less light.

In an effort to increase the life expectancy of a bulb, some manufacturers have placed a diode in series with the filament. Some of these are washer-type diodes. They are designed for insertion in the base of a lamp to provide direct current (DC) to the lamp. This causes a change in the spectrum light and a loss in brilliance. In addition, engineers report that the diodes can inject a DC component into the power supply inside the house, and this can damage computers, videocassette recorders, and other sensitive electronic equipment. Considering the loss in brilliance and change in spectrum light, the addition of a diode to try to extend the life of a bulb is not worthwhile; the diode does not provide sufficient benefits to warrant its use.

Fixtures of Incandescent Lamp

The 2002 NEC code changed the definition of fixture to luminaire. The term luminaire (lighting unit) was added throughout the NEC to replace the terms fixture and lighting fixture. Since the NEC is international in scope, and used everywhere, the term was thought appropriate. However, it will appear in parenthesis in the code until it is more generally known. Incandescent fixtures (luminaries) are usually mounted directly over a junction box. Be sure that there is proper support so that the weight is held in place without movement. Fixtures that weigh over 50 pounds have to be mounted by an independent box.

Incandescent fixtures can be recess-mounted, but these lamps generate a lot of heat and can cause a fire. For this reason insulation is not permitted within 3 inches of a fixture. This is to prevent the insulation from trapping the heat and increasing the operating temperature of the fixture. The wiring used in the recess-mounted incandescent lamp fixtures must be able to withstand higher-than-normal temperatures. Branch circuit wires cannot be mounted in the recessed fixture unless their temperature rating is sufficient to take the heat.

|

| Incandescent lights |

Fluorescent Lamps – Types of Lights

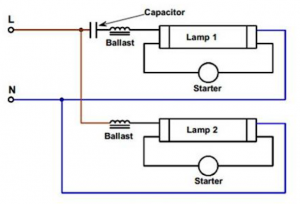

A fluorescent lamp is an arc-discharging device that has no inherent resistance. Therefore, unless it is controlled, current flow will rapidly increase until the lamp burns out. This problem is solved by the use of a device called ballast that is connected between the lamp and the power supply to limit the current to the correct value for proper lamp operation. (To “ballast” something is to stabilize or steady it, the ballast in a fluorescent lamp stabilizes, or limits, the amount of current flow.)

Read Lighting System:

Ballast – Fluorescent Lamps

One of the most practical ways to limit current to a fluorescent lamp in an AC circuit is to use a coil or inductor. Simple inductive ballasts are coils of copper wire wound around iron cores. Alternating current passes through the turns of the copper wire, creating a strong magnetic field. The magnetic field reverses its polarity 120 times per second when operating on 60-hertz AC. The resulting reactance opposes a change in current flow and limits the current to the lamp. Only a few ballasts are this simple, but the basic principle of operation is the same in all ballasts.

Fluorescent Ballast Life

The medium life expectancy of fluorescent ballasts is approximately 12 years. This means that 50% of the units installed will have failed after a period of 12 years. There are, however, several factors that affect ballast life, among them temperature, voltage, hours of use, and lamp condition. The best way to ensure full ballast life is to apply the ballast or fixture combination properly so that ballast case temperatures do not exceed 90°C. Ballasts, like other electromagnetic devices such as motors and transformers, generate heat during operation.

Ballast heat is transferred from the internal components to the ballast case through the filling medium. Once the heat reaches the ballast case, it is dissipated by conduction, convection, and radiation to the surrounding air or mounting surfaces. If these normal means of heat dissipation are not adequate, the ballast may overheat. If this occurs, coil insulation may break down, resulting in internal short circuits and ballast or capacitor failure.

Applied voltage also affects the life of a ballast. A 1% increase in voltage over the nominal design voltage will cause the ballast’s operating temperature to rise 1°C. If voltage increases continue, the ballast may overheat. Some ballasts (in Class P) now have an automatic resetting thermostat or ballast protector to prevent overheating. Duty cycle is also a consideration in the expected 12-year life expectancy. The 12-year expectancy is based on a duty cycle of 16 hours a day, 6 days a week, 50 weeks a year.

This cycle, totaling 60,000 hours of operation, would cause half of the ballasts to wear out in 12 years. However, about 4 hours of each day’s cycle are required to bring the ballast up to temperature, so the duty cycle described really totals only 12 hours a day, or about 45,000 hours, when the ballast is operating at full 90°C case temperature, during 12 years. Significant variations from the typical cycle will affect life expectancy, either increasing or decreasing it.

Failed lamps in most instant-start and preheat (switch-operated) fluorescent systems should not be allowed to remain in the fixture for extended periods of time because tins too will cause ballast overheating and result in significant reduction in ballast life. Ballasts are designed to withstand abnormal conditions resulting from a failed lamp for up to about 4 weeks, but not for extended periods. One type of ballast rapid-start ballast is not affected by failed lamps in a fixture.

Types of Fluorescent Ballasts

The overheating of fluorescent ballasts has caused a number of fires, and electrical codes now specify the use of thermally protected ballast Class P ballasts in some situations. Read NEC Section 410-73 for detailed information. All ballasts installed indoors are now required to have thermal protection integral to the ballast itself. Previously installed, old ballasts without thermal protection must be replaced with ballasts that have thermal protection.

Ballast Role in Maintaining High Power Factor

High power factor means that the line current is almost in phase with the voltage. This means near unity or 100%. A resistive load presents a 100% (or unity) power factor, whereas the inductive load presented by the fluorescent lamp ballast is normally about 0.40 to 0.60 (53o to 66o). This can be corrected with the addition of a capacitor to within 5% or 0.95 or about 18o. It is advisable to correct the power factor when a large number of fluorescent lamps are used in a building. Buying high-power-factor ballasts also improves the efficiency and lowers operating costs.

Sound

The hum produced by ballasts varies with the way the ballast is mounted on or in the fixture. The sound is rated from A to F, A being the quietest. Factories can often use ballasts with an F-rating, but libraries need A-rated ballasts. The problem of ballast hum has been investigated extensively. By installing ballasts in accordance with sound-control recommendations provided by the manufacturer, it is possible to predict the likelihood of audible hum and try to reduce or eliminate sound problems

Types of Fluorescent Lamps

There are several types of fluorescent lamps available, among them rapid-start and instant-start cold-cathode lamps that do not require a starter and preheat lamps that do require a starter.

|

| Types of Compact Fluorescent Lamps |

Preheat Fluorescent Lamp – Types of Lights

The preheat or switch start circuit is the oldest one in use today. It is used with preheat or generalline lamps requiring starters and is particularly well suited for low wattage, low-cost applications. Pushing the switch button causes the starting switch to close.

This allows the current to pass through the ballast, the starting switch, and the cathodes at each end of the lamp. The current heats the cathodes until electrons “boil off” and form clouds around each cathode. When the push button is released, the starting switch is opened. Then a higher-voltage inductive kick, caused by a sudden collapse of the ballast’s magnetic field, strikes the arc and lights the lamp. The ballast then limits, through its inductive reactance, the amount of current that flows through the circuit.

Instant-Start Cold-Cathode Fluorescent Lamp – Types of Lights

Cold-cathode lamps do not have to be heated before starting. One type, the instant-start type, was developed in the 1940s. It requires no starter. The lamp is started by “brute force”; that means by applying a high starting voltage between the lamp cathodes with no preheating it starts.

There are two types of two-lamp, instant-start circuits. One, called the series circuit, has a lower initial cost but does not provide independent lamp operation. The other type, the more expensive lead-lag circuit, provides not only independent lamp operation, but also reliable starting, even in low temperatures.

Rapid-Start Fluorescent Lamp – Types of Lights

The rapid-start ballast circuit is the most popular in use today. It is used with rapid-start (430 mA), high-output (800 mA), and extra-high-output (1500 mA) lamps. Rapid start lamps use cathode heating continuously during lamp operation. No starter is required. The cathodes are designed to heat quickly once the switch is turned on. Current begins to flow through the tube almost instantly. Rapid-start fluorescent lamps require special ballast so that the lamp cathodes are quickly heated.

Starters

A starter is needed to automatically start some preheat types of fluorescent lamps. They can be manually started if you use a switch or automatic if you use a sealed glow switch. The glow switch consists of a can-covered glass envelope. Inside the envelope is a stationary post and a movable bimetallic post. Neon or argon gas under pressure is injected into the envelope and it is sealed. If it has an orange glow it is neon. When the lamp is turned on, the bimetallic strip begins to glow. When it glows, it heats up.

As it heats up, the movable end begins to move toward the stationary contact pole. Once the bimetallic strip makes contact with the stationary pole, current travels through the cathode at each end of the tube, causing the cathodes to heat up. Once the bimetallic strip makes contact with the stationary pole, the bimetallic strip begins to cool. As it cools, the movable end moves away from the stationary post and the circuit is broken. By the time, the circuit is broken, the gas in the lamp has ionized and started to conduct and produce light, and there is no longer a need for the starter in the circuit. It is ready to be used again once the circuit has been turned off and then on again.

Fluorescent Fixtures and Bases

Fluorescent fixtures are usually sold by the manufacturer already wired, and they need to only be connected to a source of AC power, usually 120 volts. The rating of the wire used to serve these fixtures has to be such that it can withstand 90°C (194°F), or the wire cannot be placed within 3 inches of the ballast. (Type THW wire can be used for this purpose.)

Very little heat is generated by a fluorescent fixture, but it has to be taken into consideration whenever the fixture is mounted in hazardous environments. Special types of fixtures are available for use in spray-painting booths and similar environments, and fixtures to be used in explosive atmospheres or agricultural environments must meet special requirements set by the NEC. Read Section 410-4.

Fluorescent fixtures may be flush-mounted or recessed. Fluorescent lamp fixtures that are flush-mounted to a box on the ceiling have to be arranged so that they cover the box completely. A hole in the fixture is needed to provide access to the junction box. If the hole is not located in the proper place, use a hole punch of some type to make a hole for access to the wiring. Read NEC Sections 410-14(b) and 410-12 for further details.

Special fixtures are made for a recessed installation. T-bars are used to fasten the fixture to the ceiling joists. In a commercial location, conduit usually feeds a junction box and flexible conduit or BX is used from the junction box to the fixture.

Fluorescent lamps that are installed in an industrial plant may be mounted to a raceway or to overhead pipes. In these cases, the lamps must be cord-connected to an overhead junction box directly in the fixture. Fluorescent tubes are available with single-pin and bi-pin bases in different sizes. The type of base must be matched to the fixture installed.

Troubleshooting Fluorescent Lamps

Tips for troubleshooting fluorescent lamps are given in this article.

Other Types of Lights or Lamps

In addition to incandescent and fluorescent lamps, there are other sources of light, among them are mercury vapor lamps, metal halide lamps, and sodium lamps.

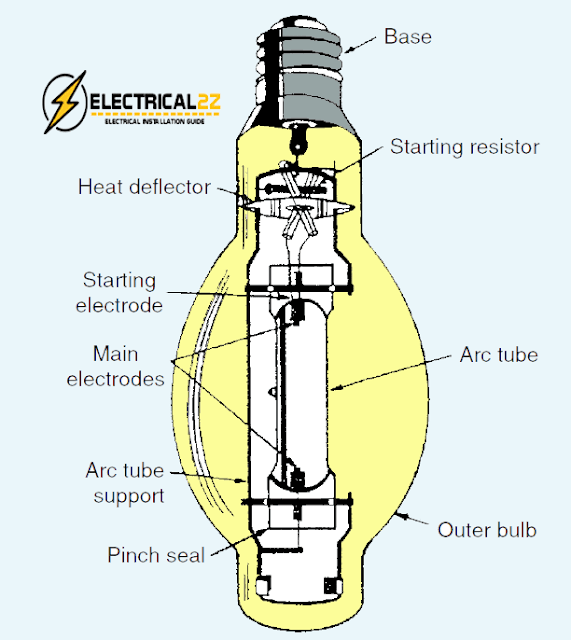

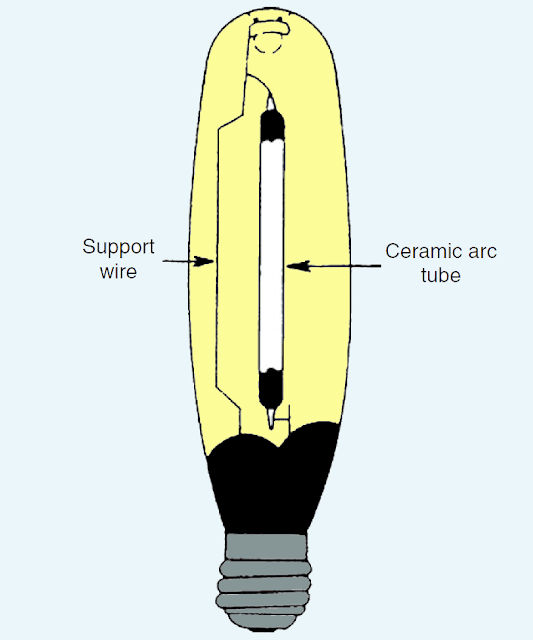

Mercury vapor lamp – Other Types of Lights

Mercury vapor lamps are commonly used in shopping centers, parking lots, in large farmyards, and along highways. A mercury vapor lamp is an arc-discharging, non-filament device. Once the arc is struck and the unit is emitting light, some type of ballast is usually required to limit the current flow to the device. There are two general types of mercury vapor lamps:

1. Those that require the addition of a ballast some place on the fixture.

2. Those that are self-ballasted.

|

| Mercury Vapor Lamp @ Types of Lights |

The two types are similar in appearance, and you must be careful to screw the bulb only into a socket designed for its specific type. Many mercury vapor lamps mounted on poles in parking lots, in farm-yard, or along the highways have a photoelectric eye that turns the fixture on at dusk and off at dawn. Often the lamp needs time to warm up to full brilliance.

Possible problems with mercury vapor lamps include a burned out lamp, a loose or broken wire, a bad photoelectric switch, and, if the lamp is not self-ballasted, a burned-out ballast. The more often the lamp is started, the shorter its life expectancy. The mercury vapor lamps used on farms and in commercial parking lots last about 24,000 hours, or 7 years when used with an automatic on-off switch for operation every night.

The best way to troubleshoot a mercury vapor lamp is with a meter. Check the bulb first to see if it is operational. Then check the on-off switch or photoelectric switch. To do this, short the two wires to the switch together. If light comes on, the switch is not defective. Remember, however, that it may take a few minutes for the lamp to begin to glow. If the bulb is not self-ballasted, disconnect the ballast and test it with an ohmmeter for shorts and opens.

A cracked mercury vapor bulb can give off harmful radiation and damage the eyes and skin. Most, however, are safety bulbs, that will burn out almost immediately if the bulb is cracked.

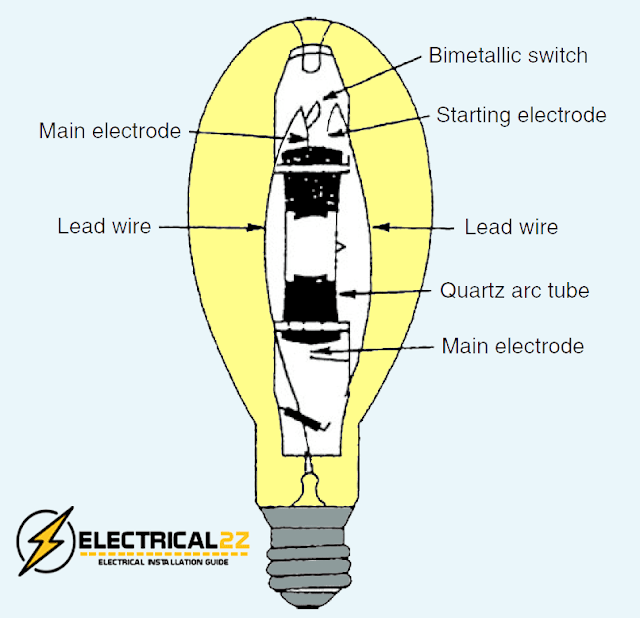

Metal Halide Lamps – Other Types of Lights

The halide family of elements consists of mercury, sodium, thallium, indium, and iodine. The metal halide lamp contains many of these metals and puts out a better-quality light than a lamp containing only mercury. Colored objects appear their normal color under this type of lamp another advantage. Metal halide lamps are used for sports-lighting, outdoor-produce market lighting, and wherever a bright light with true colors is needed.

|

| Metal halide lamps @Types of lights |

Metal halide lamps operate with the base up or down. However, you must know which. Otherwise, you can ruin the lamp because the starting switch inside the lamp will not operate properly unless it is mounted correctly. Do not place a metal halide lamp in a fixture designed for a mercury vapor lamp, and be sure the metal halide lamp will operate in the fixture that you have for it. Although the metal halide lamp provides bright, true-color light, there are some disadvantages associated with it. It is more expensive than the mercury vapor lamp, lasts a shorter time, and produces a steadily decreasing amount of light with age.

High Pressure Sodium Lamps – Other Types of Lights

A high-pressure sodium lamp contains xenon gas, along with mercury and sodium. When the gases are vaporized by an electric arc, the glow gives a very intense light. The color of the light is somewhat yellowish-orange but objects under it appear almost their natural color. High-pressure sodium lamps are used primarily as farm lights. They are more efficient than mercury lamps and give off about twice as much light for the same wattage, and can produce light much faster (within 2 minutes) than mercury vapor lamps. They do, however, cost more and need special ballast.

|

| High Pressure Sodium Lamp @Types of Lights |

Low Pressure Sodium Lamps – Other Types of Lights

A low-pressure sodium lamp produces an orange color and gives objects under it an off-color cast. It can be used where high illumination is needed with little need for true color. A low-pressure sodium lamp makes a good security lamp. Lamp life is about 18,000 hours with special ballast and fixture.

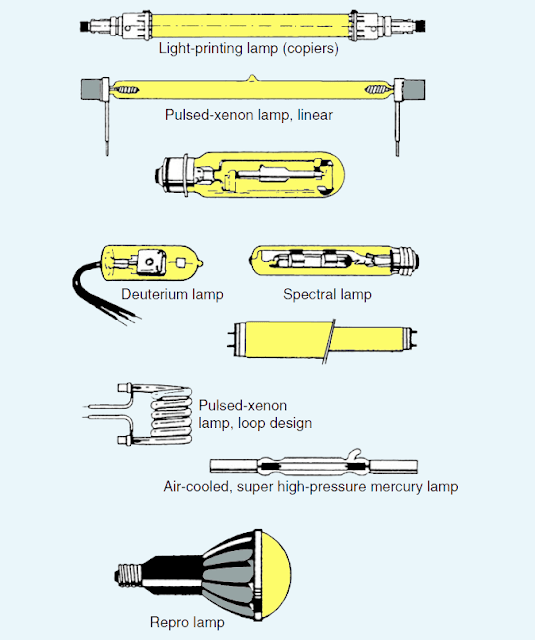

Other Types of Lights or Lamps

There are many other types of lamps, including ballasted mercury vapor lamps, compact-source iodide lamps, high-pressure mercury vapor lamps, repro-lamps, black light lamps, water-cooled, super high- pressure mercury lamps, air-cooled, super-high-pressure mercury lamps, quartz tubes, pulsed xenon lamps, super actinic lamps, spectral lamps, and neon lamps.

|

| Some other types of lights |

Final Word

Hope you understand this article about Different Types of Lights. Incase of any doubt please comment below. Subscribe our website to get every new post update to your email. Please follow our website – ElectricianWorld.Net for future updates. Thank you for visiting our website.