In a vacuum circuit breaker, the arc interruption takes place in vacuum. This technology has been found to be most suitable for medium voltage application though the experimental interrupters for 72.5 kV and 145 kV have been developed, they were not found to be commercially viable.

Vacuum Circuit Breaker Principle

In principle, a vacuum interrupter has a steel arc chamber in the center and symmetrically arranged ceramic insulators. Figure showing the main parts of a typical vacuum interrupter. Modern constructions of this interrupter have a metal shield surrounding the arcing contacts. The diameters of the contacts and their stems are matched with those of the arc chamber and insulators. The moving contacts are made movable by the use of metallic bellows. The arc chamber is welded to the housing flanges, which, in turn, are brazed to metallized ceramic insulators, thus giving a hermetically sealed interrupter. The vacuum pressure is generally 10~ bar.

|

| Vacuum interrupter – VCB Breaker |

The material of the contacts plays a very important role in the overall performance of the vacuum circuit breaker (VCB), and, in fact, the entire development of vacuum technology is centred around the use of proper material and geometry of the contact. The most common materials used today are CuBi, CuCr, or CuAg. Of these, CuCr offers the most ideal solution for all ratings of interrupters from 8 kA to 63 kA. With this material, the current chopping levels have been kept down to as low as 2 to 3 amps.

Even though modern vacuum interrupter (VI) technology was developed in the early 1960s, it is still considered to be an evolving technology, as continuous improvements and innovations are taking place in this area. For example, the size and capability of modern VI bears no relationship to the one built in the 1960s.

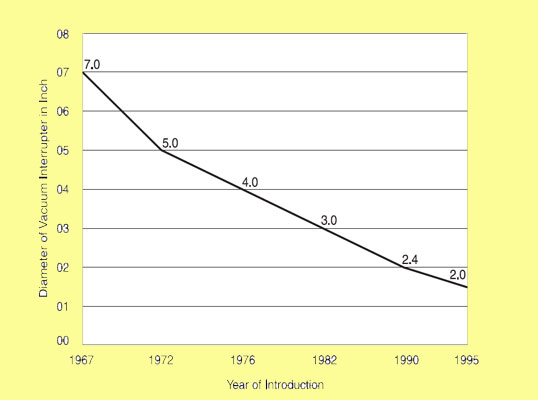

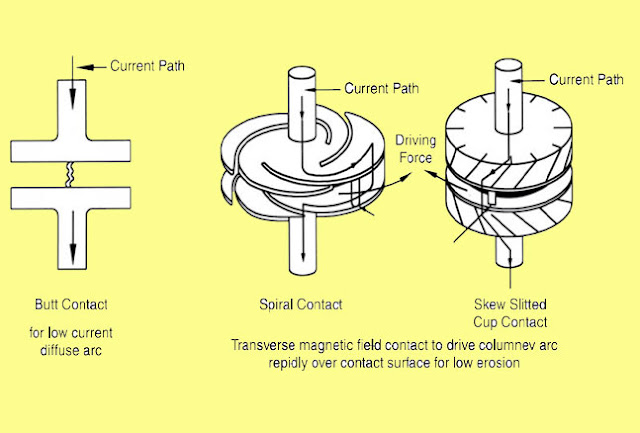

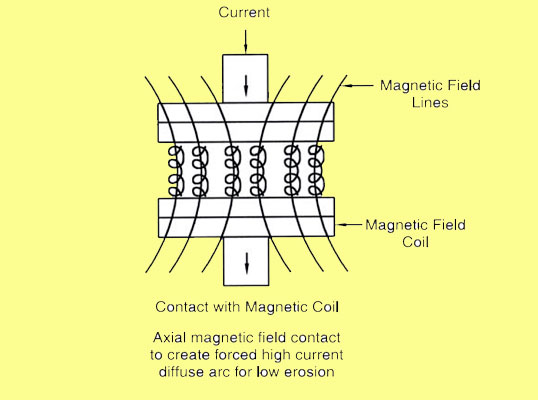

Image shows an example of 12 kV, 12.5 kA VI wherein it can be seen that the diameter of the VI has been reduced from 7 inches in 1967 to 2 inches today. This size reduction is the result of major developments in vacuum technology, vacuum processing, contact material development and evolution of vacuum interrupter design. The contact geometry started from plain butt contacts in the 1960s and gradually progressed to spiral, cup and axial magnetic fields.

The butt contact is the simplest, but is only suitable for interrupting the low current diffuse vacuum arc. It thus finds application in load break switches and contactors which are required to interrupt currents less than 4.5 kA. The transverse magnetic field (TMF) contacts have spiral or skew silted cup type construction.

These contacts use the transverse magnetic field generated by the circuit current flowing in the spiral arms or skew slits of contacts to drive the high current, columnar, vacuum are rapidly over the contacts surfaces. This results in two effects: (a) the contact surface has uniform erosion and is left in a relatively smooth condition after high current arcing, and (b) the column cannot sustain itself when the current falls to current zero in an ac circuit. It thus returns to the diffuse mode, which is easily interrupted at current zero.

|

| Reduction in size of vacuum interrupter for 12 kV, 12.5 kA rating |

The application of the VI to protect power distribution circuits has grown during this period. In fact, the vacuum circuit breaker (VCB) is today recognized as the most reliable, and it also needs the lowest maintenance among all the technologies available to control and protect distribution circuits. The present consensus all over the world is that the VCB breaker will dominate medium voltage technology in the twenty-first century.

Applications of VCB Breaker

It is becoming increasingly difficult for SF6 breaker to compete with VCB breaker technology in the following three major areas:

(a) Long life: it is now possible to produce cost-effective VI designs with electrical lives that exceed the required mechanical life of the circuit breakers, and that will even be able to satisfy a recent requirement of extended short circuit operating life.

|

| Contact geometry and their effect 1.1 |

(b) Environmentally benign: VIs are constructed from environmentally benign materials and do not pose the potential health risk that exposure to arced SF6 gas does. Also VIs do not need special hazardous waste handling that SF6 interrupters require when routine maintenance is performed or when the SF6 interrupter is disposed of at the end of its life.

(c) Overall superior performance: Besides above, the construction of VI’s is very user friendly for easy mounting in this circuit breakers. Replacement of VI’s whenever required is also very convenient. This is a direct result of the extensive R&D work undertaken up by universities and the manufacturers of VI’s.

|

| Contact geometry and their effect 1.2 – Vacuum Circuit Breaker |

Final Word

Hope you understand this article about Vacuum Circuit Breakers | VCB Breaker. Incase of any doubt please comment below. Subscribe our website to get every new post update to your email. Please follow our website – Electrical2z @E2Z for future updates. Thank you for visiting our website.

It’s amazing to visit again n again coming to your blogs the superb effort is here.

a kind of circuit breaker where the arc quenching takes place in vacuum medium. The operation of switching on and closing of current carrying contacts and interrelated arc interruption takes place in a vacuum chamber in the breaker which is called vacuum interrupter.

URL: https://www.affordablelectricians.com.au/electrician-mitcham.html

What is the function of vacuum circuit breaker?