The article is all about how to do the building electrical installation maintenance and operation. For the lighting installation electricians commonly used the electrical conduit pipes to make cable ways in the buildings. Electrical cable trays not usually installed in the building construction. In domestic lines, cable glands usage is unnecessary for the electrical cables. The guide is completely covered about the topic. so, read carefully without skip any paragraph.

|

| Building Electrical Installation Maintenance Guide 2019 |

Table of Contents

Building Electrical Installation – Points To Be Inspected for Maintenance

Every part of the installation should be checked by a responsible official and preferably recorded

in a register or entered in a tabulated form.

In brief, this consists of the following inspections:

1. Service connection.

2. Main switchboard.

3. Internal wiring and its insulation.

4. Earth tests and bonding.

5. Switches and fuses.

6. Portable apparatus.

7. Fire precautions.

If the annual inspections are carried out conscientiously, most of the defects come to light and

could be corrected before they result in a serious breakdown or accident. Some of these defects

would perhaps be installation defects and a few even due to faulty design. Both these aspects will,

therefore, have to be borne in mind, when carrying out inspections.

Insulation Resistance Measurement Procedure

Megger value for insulation test of the electrical wiring is a 500V and comprises mainly two parts, viz., line to earth test and line to line test. Before starting the tests, switch off the supply, remove the main fuses and disconnect the neutral link. Then proceed as follows:

Line To Earth Test

- First, insert all fuses at the fuse board and insert all the fluorescent lamps and also close all the single pole tumbler switches. where fans are provided, close the fan switches and put the regulators in the ‘on’ position.

- Now just short the phase and neutral terminals on the dead side of the main switch and connect them to one terminal of the megger. The other terminal is connected to the earth, or the conduit in which the wiring is run, or if the wiring is in lead covered cables, to the lead sheathing.

- Note and record the megger reading.

|

|

Line To Line Test | Building Electrical Installation

|

Note : where 2-way staircase type switches are provided, reading should be taken in both

positions of the switch

This gives the total combined insulation resistance to earth of both the phase and the neutral

conductors (I.E.E Wiring Regulation – 1103), The minimum permissible resistance should be not less than 50/ no. of outlets

Interview tip: Know IEE full form – Electrical Abbreviations

If there are 30 wiring points, the insulation resistance should not be less than 50/30 i.e. 2 ½ megaohms. If the megger show the value below than that, it cannot be considered as satisfactory. The insulation resistance of each sub-circuit should than be taken individually and the faulty section located and attended to each final sub-circuit should have a resistance of at least .5 megaohms, under the worst conditions, i.e. during the rainy season when wiring is damp.

Line To Line Insulation Test on Building Electrical Installation Maintenance

- Disconnect all the consuming devices such as lamps, fans, or portable apparatus plugged on to 2 or 3 pin sockets, etc.

- Keep all single pole tumbler switches in the ‘on’ position.

- Remove all fuses in the fuse boards, and open the neutral link.

- Take the insulation resistance between the phase and neutral lines of each final sub-circuit for simplicity, a single circuit alone is shown. The insulation resistance between lines of each final sub-circuit should be not less than 5 megaohms for 10 wiring points. If the readings are lower, the cause must be located and rectified.

I.E rule No.48 states that the maximum permissible leakage on the consumers’ premises is 1/5000th part of the maximum current supplied to the consumer. Thus, if the maximum load on the premises is say, 5 amps. On a 230 volts system (1150 watts), the maximum permissible leakage is 5/5000=1 milliampere. On a 230 volts circuit, the minimum insulation resistance should, therefore, be 2,30,000 ohms or .23 megaohms. The above tests would reveal nearly all insulation defects in a wiring installation. Insulation resistance of all portable apparatus such as electric irons, heaters, etc. should, however, is taken separately.

|

|

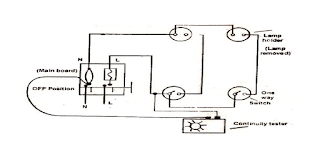

Continuity Test

|

Points To Be Checked in Switches and Fuses – Building Electrical Installation Maintenance

The following points should be checked:

1. Every fuse should be of the correct size. The correct size should be indicated on the fuse board or the main board as the case may be. Examine the fuse wire; if it shows any signs of overheating or sulphation, renew it.

2. The main contact jaws of all switches should be cleaned and lightly vase lined.

3. The inlet and outlet holes in iron clad switchgear, fuse boards, etc. should be properly protected by means of suitable insulated bushes. The leads themselves should be taped up, protected with insulating varnish and sealed with compound to prevent moisture or water from getting into the equipment.

4. All switches, fuses, etc. should be properly numbered to facilitate identification of circuits. The main switch should also be prominently marked to facilitate quick identification and to comply with the I.E rules.

5. The V.I.R. connection inside wooden distribution boards should be rearranged and taped up. Renew them if necessary.

6. Every single pole tumbler switch should be tested for its being correctly connected in the phase line. It shall under no circumstances be connected in the neutral line. This can be checked by a test lamp, connected between the earth and the switch terminal, with the switch in the closed position. If the lamp burns, it proves that the switch is in the phase line. It is, however, very important to remember, when conducting this test that the tumbler switch should be kept closed. If this precaution is not taken, the results will be misleading. The switch connected in the neutral line is incorrect.

Yet the test the test lamp will light up since the test lamp and the main lamp are in series across the supply. Both of them will light up but they will be dim. Since the test lamp lights up one is likely to conclude erroneously that the switch is in the phase line even though it is not.

The correct method of conducting this test is to keep the switch closed the test lamp will then not light up unless the switch is in the phase line.

|

| Single Switch |

Points to be Inspected in Portable Electrical Equipment

1. The insulation resistance of the conductors should be checked by a megger. If the reading is low, the cause must be investigated and rectified. Frequently the cause is perished lead-in connections due to chafing of the leads.

2.On effective cable grip should invariably be provide on every portable apparatus and also at the plug end, where flexible cable connections are made the effectiveness of the cable grip should be checked periodically, the internal connections should not get disturbed when the cable is pulled, jerked or twisted, But the grip pressure itself should not pinch the insulation unduly. It is a good practice to redo the connections periodically after cutting off the exposed ends of the cable. in the absence of a cable grip of good design , the cable may be looped and bound to the handle by whipcord as a temporary expedient.

3. Where interlocked switch plugs are provided, check if the interlocking action is effective, i.e. it should not be possible to close the switch without the plug in position, nor to withdraw the plug when the switch is in the closed position.

4. In the case of heavy equipment like a refrigerator, heater or boiler which remains more or less in a fixed position, an independent permanent earth connection should be made to the metal casing of the equipment by a copper wire of sufficient section (8S.W.G), in addition to the usual earth connection derived from the plug socket through the connecting cable, as a further measure of safety.

5. When making cable connections take care to see that the wire ends are twisted and bend into a neat eyelet, to take in the screw securing it. The wire end should always be placed clockwise below the screw head so that the end may tend to close inside inwards when the screw is tightened; if placed anticlockwise, it will tend to open out and get loose. Use a washer immediately below the screw head to ensure that the wire is firmly gripped.

6. Whenever wiring is passed through a hole in a metal body, it should invariably be protected and insulated by a bush.

7. Flexible wire ends should be neatly twisted together and preferably soldered so that there may be no loose strands; Such loose strands may come in contact with the metal body of a lamp holder or adjacent terminals causing as accident or short circuit.

8. The outer insulation of wires should only be stripped to the minimum extent necessary. If stripped too long, there is every possibility of a short circuit.

9. Lamp holders: The screw securing the wire end should be of proper length. If too long, it may touch the body of the lamp holder. If the porcelain interior is wrongly assembled the locking nick in the outer brass. Ring may touch the live terminals. For Hand Lamps, Porcelain or Bakelite lamp holder should be used as far as possible as brass lamp holders are not so safe.

|

| Double Switch |

Action to be taken If electrical equipment catches with fire

The following are the steps:

- Switch off the main supply.

- Use fire extinguishers recommended for the electrical fires.

- Water should not be used.

- Sand should not be used on electrical machines/equipment; this may be used for other purposes.

- There should be provision for fire extinguishers and buckets filled with sand on every large installation or industry.

Hope you understand this article about the Building Electrical Installation Maintenance Guide. Incase of any doubt please comment below. Subscribe our website to get every new post update to your email. Please follow our website @ElectricianWorld.Net for future updates. Thank you for visiting our website.