Wind Power Plant | Wind energy describe the process by which the wind is used to generate mechanical power or electricity. Wind turbines convert the kinetic energy in the wind into mechanical power. This mechanical power can be used for specific works (like grinding, pumping) or a generator can convert this mechanical power into electricity.

Table of Contents

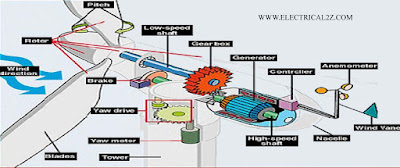

Basic Components of a Wind Power Plant

The following components are mainly used components in wind plant.

- Tower

- Nacelle

- Rotor Blades

- Shaft

- Gearbox

- Generator

- Power Converter

- Anemometer

- Wind Vane

- Pitch Drive

- Yaw Drive

|

| Wind Power Plant – Components |

Tower

The tower is very crucial part of turbine which is supports all the other parts. It is not only support the parts but raise the turbine so that its blades safely clear the ground and so it can reach the stronger winds at higher elevations. The height of tower depends upon the power capacity of wind turbines. Large size wind turbines usually mounted on tower ranging from 40 meter to 100 meter.

Nacelle

It is big box that sits on the tower and house all the components in a turbine. Nacelle houses power converter, shaft, gearbox, generator, turbine controller, cables, yaw drive.

Rotor Blades

Rotor blades are the mechanical part of the wind turbine that converts kinetic energy into mechanical energy. When the wind forces the blades to move, it transfers some of its energy to the shaft. Rotor blades are shaped like airplane wings. Length of the blade is 150 feet.

Shaft

In the wind power plant, the shaft is connected to the rotor. When the rotor spins, the shaft spins as well. In this way, the rotor transfers its mechanical, rotational energy to shaft that enters to the generator on the other end.

Gearbox

The rotor turns the shaft at low speed example 20 rpm but to generate electricity, generator needs higher speed. Gearbox increases the speed to much higher value required by most generators to produce electricity. E.g. if gearbox ratio is 1:80 and if rotor speed is 15 rpm then gearbox will increase the speed to 1200 rpm that is given to an electric generator shaft.

Generator

Electrical generator is device which converts mechanical energy received from shaft into electrical energy. Generator works on electromagnetic induction to produce voltage or current. A simple electrical generator consists of magnets and a conductor. The conductor is typically a coiled wire. Inside the generator shaft connects to an assembly of permanent magnets that surrounded by magnets and one of those parts is rotating relative to the other, it induce the voltage in the conductor. When the rotor spins to the shaft, the shaft spins the assembly of magnets and generate voltage in the conductor.

Power Converter

Electrical potential generated from generator is not constant cause wind is not always constant but we need a very stable voltage to feed the grid. Power converter is a device that stabilizes the output alternating voltage transferred to the grid.

Anemometer

The meter measures the wind speed and passes the speed information to PLC (Programmable logic control) to control the turbine power.

Wind Vane

Wind vane senses the direction of wind and passes the direction to PLC then PLC faces the blades in such a way that it cuts the maximum wind.

Pitch Drive

Pitch drive motors control the angle of blades whenever wind changes it rotates the angle of blades to cut the maximum wind.

Yaw Drive

Power converter, shaft, gearbox, generator, turbine controller, cables, and blades in wind turbine is housed in Nacelle, whenever any change in wind direction is there Nacelle has to move in the direction of wind to extract the maximum energy from wind. For this purpose yaw drive motor is used to rotate the nacelle. Yaw drive is controlled by PLC which uses the wind vane information to sense the wind direction.

|

| Wind Power Plant Working |

Working Principle of Wind Energy Plant

The rotor blades start to rotating when the wind strikes the blades. In the high speed gear box, rotor is connected directly. Gearbox converts the rotor rotation into high speed which rotates the generator.

An exciter is needed to give the required excitation to the coil so that it can generate required voltage. The exciter current is controlled by the wind turbine controller which senses the wind speed based on that it calculate the power what we can achieve at that correct wind speed.

Then output voltage of electrical generator is given to a rectifier and rectifier output is given to line converter unit to stabilize the output ac that is feed to the grid by a high voltage transformer.

An extra units is used to give the power to internal auxiliaries of wind turbine this is called internal supply unit. SU can take the power from grid as well as from wind. Chopper is used to dissipate extra energy from the rotor unit for safety use.

Advantages of Wind Energy

- Wind power plant is Eco-friendly.

- It is relatively inexpensive.

- Wind energy has enabled electricity reach in remote locations.

- It’s a steady and reliable source of electricity.

- Wind turbines take up less space.

- Wind energy contribute to job creation.

Disadvantages of Wind Energy

- Wind energy is variable.

- Turbine blades can pose great danger to local bird species.

- The initial infrastructure is costly.

Hope you understand this article about the Wind energy – Wind power plant working and advantages. In case of any doubt please comment below. Please follow our website for future updates. Thank you for visiting our website @ElectricianWorld.Net

Wind energy is one of the renewable source which is the low pollutant plant…